Custom Brass Fabrication Services

Gieske has offered superior custom metalwork for more than 100 years. We provide services for brass custom metal fabrication projects in Kansas City and facilitate select projects across the country.

The Sleek and Modern Aesthetic of Brass Can Elevate Any Space

Brass is versatile, beautiful, and strong, making it the perfect choice for statement pieces and one-of-a-kind projects. Use brass fabrication to elevate your space with:

- Custom hardware

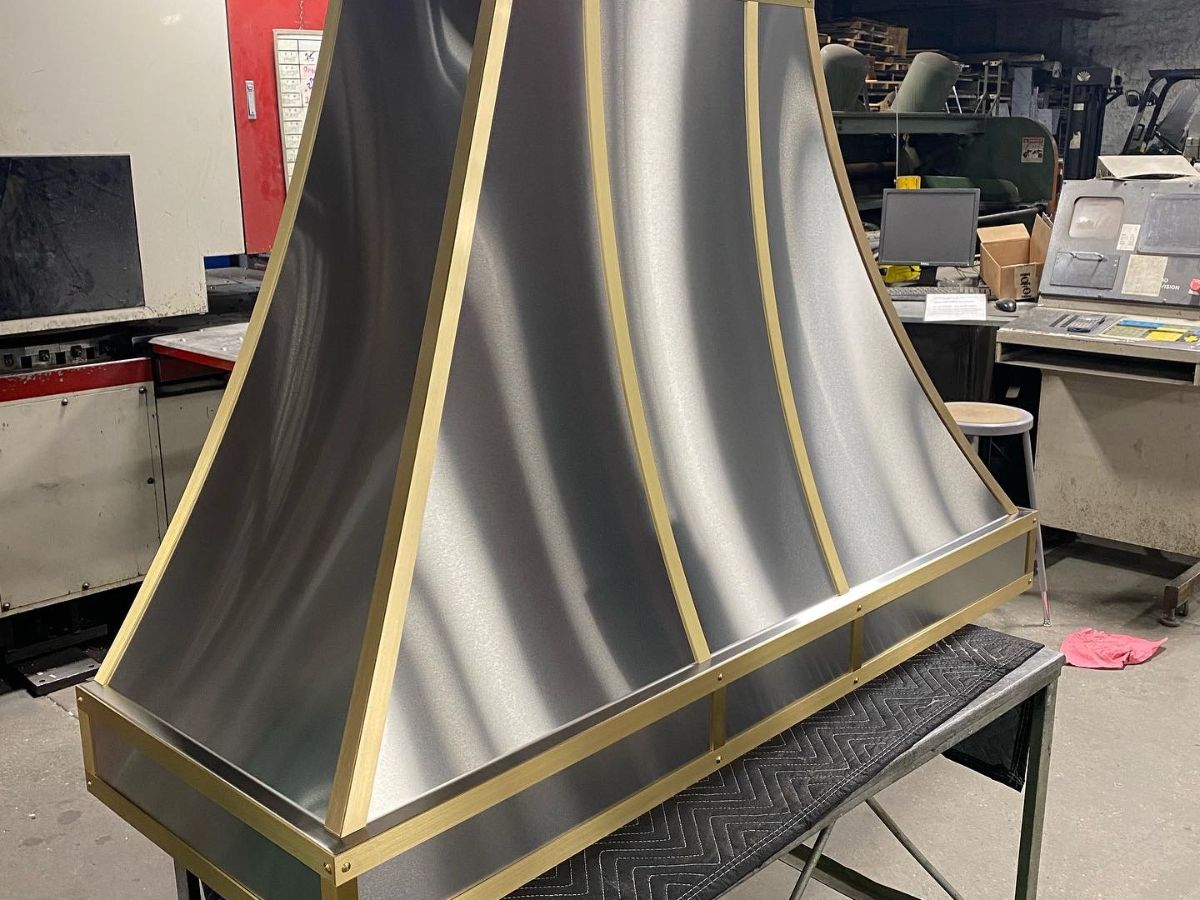

- Kitchen range hoods

- Light fixtures

- Table bases

- Window panel frames

- Architectural doors

- Art installations

- And more

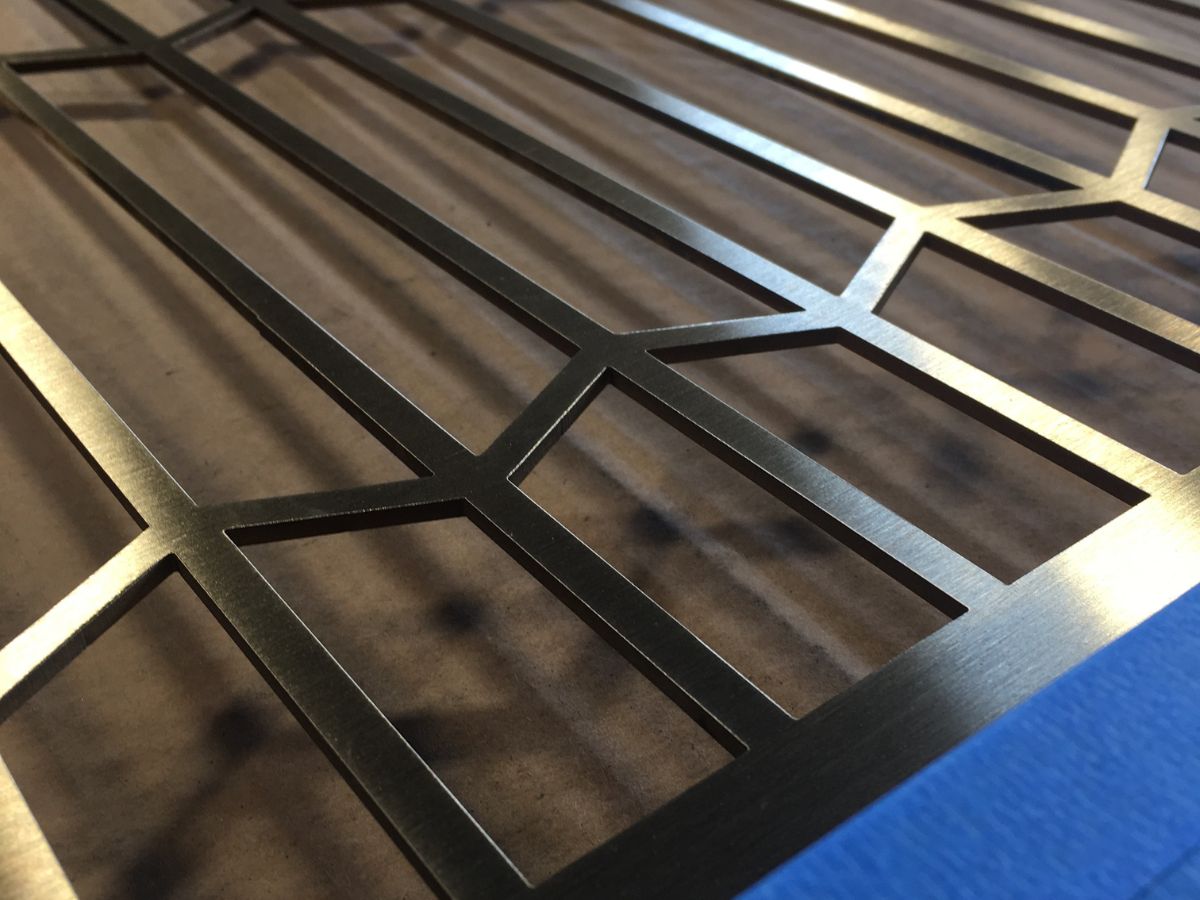

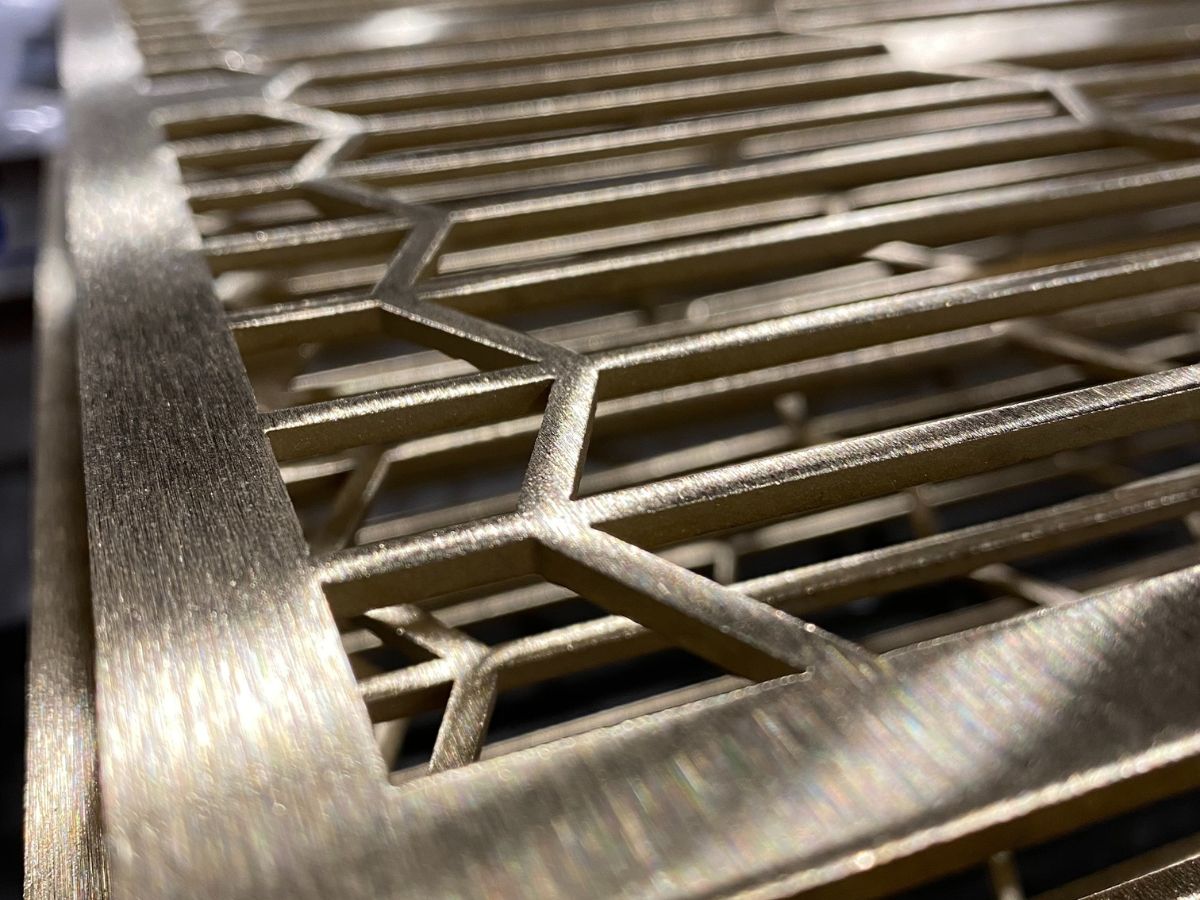

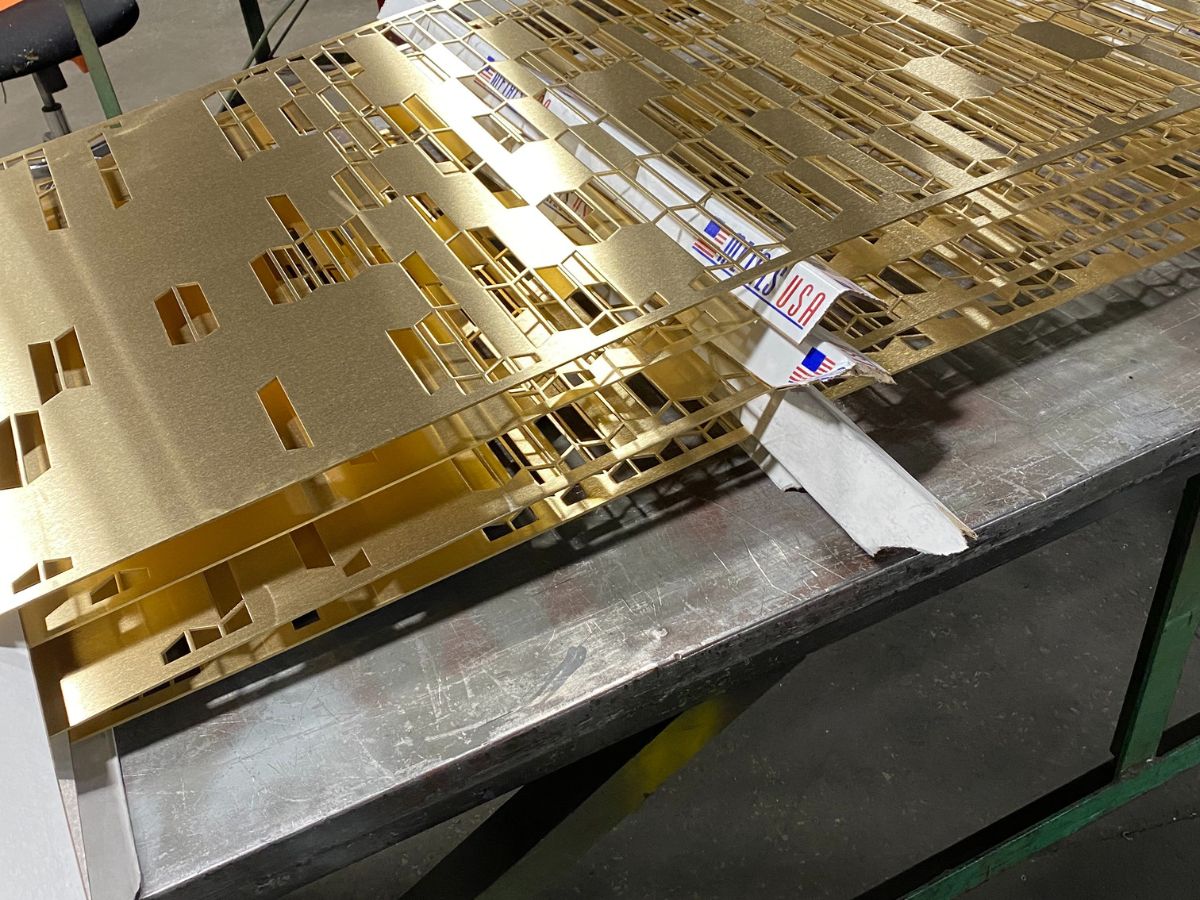

Examples of Our Brass Metal Fabrication Projects

We’ve collaborated on brass fabrication projects for a variety of applications, big and small. Take a look at some of our completed brass sheet metal fabrication projects, and contact us with a design to get started on yours.

Get a quote today!

Or give us a call at (816) 471-2300

Techniques and Equipment Gieske Uses To Fabricate Custom Brass Products

Cutting

Cutting brass sheet metal is typically the first step in the fabrication process. It may be one of many steps or the only step required for the project. Regardless, we achieve the precise cuts needed to complete any brass fabrication project using state-of-the-art equipment:

- CNC high-speed laser cutting

- CNC water jet cutting

- CNC plasma shape cutting

- Hot chop saw

- Cold saw

- Metal plate shear

- Large band saw

Forming

To achieve the desired shape for the project, we form the cut pieces using equipment that bends, rolls, or presses the brass sheets. During this process, the shape of the metal is transformed, but it does not lose any of its mass. Gieske utilizes a variety of equipment to shape brass, including:

- CNC brake

- CNC tube bender

- Powered slip rolls

Joining

Once the components of the project have been cut and formed, the next step of the brass fabrication process is joining—where the parts are assembled using either mechanical or fusion techniques. Our brass fabrication joining techniques include:

- TIG welding

- Drill press

- Soldering & brazing

- Riveting

Finishing

We offer a wide range of finishing options to meet the specific requirements of your project. In-house, we provide polishing services that can achieve a brushed, mirrored, or angel hair finish using various techniques:

- Hand finishing

- Custom grinder finishing

- Cloth buffing wheels

- Orbital sander

- 8’ Directional belt sander

- Drill press

Additionally, we regularly collaborate with external partners to offer other finishing options such as powder coating, plating, anodizing, and more.

Gieske’s Custom Brass Fabrication Process

Getting Started

Contact us with the details of your brass fabrication project by filling out our online form or calling us at (816) 471-2300.

Design & Planning

We’ll work with you in the final design phase of your project to reduce the need for revisions and minimize back-and-forth communication.

Fabrication

Our team of expert brass craftsmen will fabricate your project based on precise specifications. We’ll keep you updated on our progress along the way.

Installation

If you are located within ~100 miles of Kansas City, we will work with you and your team to provide expert installation of the final product. Otherwise, if your team has installation questions, we’ll be happy to provide what assistance we can over the phone.

We bring…

Expertise

High-Quality

Fast Turnaround

Amazing Design Work

Your FAQs Answered by Our Expert Brass Fabricators

What is brass fabrication?

Brass fabrication is the process of cutting, forming, and joining brass sheet metal into various products, parts, or structures. It involves techniques such as welding, forming, and polishing to create items for industrial, commercial, and residential use.

What are the benefits of using brass in fabrication projects?

Brass offers several advantages, including high corrosion resistance, excellent electrical conductivity, low friction properties, and a visually appealing appearance that can be finished in a variety of ways. These qualities make it ideal for applications across all industries.

What types of brass sheet metal do you work with?

We work with various grades of brass. Each grade has unique properties suitable for different applications, from corrosion resistance to strength and durability. We’ll work with you during the final design phase to ensure the most applicable grade of brass sheet metal is chosen for the intent of your project.

How much does a custom brass metal fabrication project cost?

The cost of a custom brass fabrication project varies significantly based on the project’s scope, the materials needed, the techniques and equipment employed, and whether our team will handle the installation. Please contact us with your project’s details and design, and we will provide you with a no-obligation quote.

How long will it take to complete a brass fabrication project?

While we pride ourselves on fast turnaround times, every project is unique, and there are several factors that determine how long a project will take to complete. We’ll provide you with an estimated timeline and completion date during the quoting process.

Other Materials We Work With