Custom Steel Fabrication Services

Providing superior custom metal works for more than 100 years, Gieske offers steel fabrication in Kansas City and facilitates select projects across the country.

From Large Structural Steel Fabrication Projects to Small Fabricated Machine Parts, We Can Tackle It All

Steel is extremely durable and long-lasting while also being a cost-efficient and highly customizable material. Our fabrication shop specializes in steel fabrication projects big and small, including:

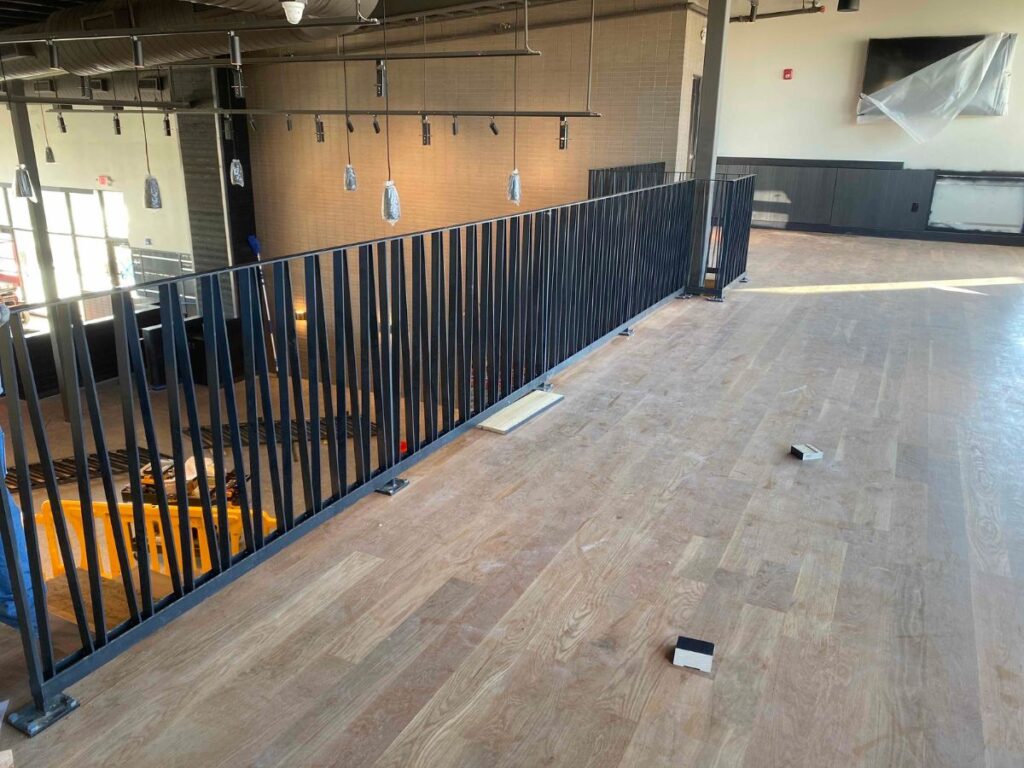

Examples of Our Steel Fabrication Projects

We’ve provided steel fabrication services for a variety of applications, big and small. Take a look at some of our completed projects and contact us with a design to get started on yours.

Get a quote today!

Or give us a call at (816) 471-2300

Techniques and Equipment Gieske Uses for Custom Steel Fabrication

Cutting

Cutting steel sheet metal is one of the most common steps in the steel fabrication process. It might be the first of many steps involved in the full fabrication process or the only step needed for the project. Either way, we utilize state-of-the-art equipment to achieve the cuts needed to complete any custom steel fabrication project:

- CNC high-speed laser cutting

- CNC water jet cutting

- CNC plasma shape cutting

- Hot chop saw

- Cold saw

- Metal plate shear

- Large band saw

Forming

During the steel fabrication process, steel is distorted into the desired shape with equipment that bends, rolls, or presses the metal. During the forming stage of steel fabrication, the metal does not lose any mass—only the form changes. Gieske uses various pieces of equipment to form steel, including:

- CNC brake

- CNC tube bender

- Powered slip rolls

Joining

Once the steel components are cut and formed, the next typical step of the steel fabrication process is joining—connecting pieces of steel together to create the final product. There are many joining techniques (both fusion and mechanical). Some of our joining techniques for steel fabrication include:

- TIG welding

- MIG welding

- Drill press

- Soldering & brazing

- Riveting

Finishing

The final step of the steel fabrication process is finishing. There is a wide range of finishing options to meet the specific requirements of your project. In-house, we provide polishing services that can create a brushed, mirrored, or angel hair finish using various techniques, including:

- Hand finishing

- Custom grinder finishing

- Cloth buffing wheels

- Orbital sander

- 8’ Directional belt sander

- Drill press

Additionally, we regularly partner with outside companies to provide other finish options such as powder coating, plating, anodizing, and more.

Gieske’s Custom Steel Fabrication Process

Getting Started

Contact us with the details of your steel fabrication project. You can give us a call at (816) 471-2300 or fill out our online contact form.

Design & Planning

We’ll partner with you in the final design phases to limit back and forth and reduce the need for revisions later on.

Fabrication

Our team of expert craftsmen will fabricate your project to the exact specifications, keeping you informed of our progress along the way.

Installation

If your project is located in the greater Kansas City area, we’ll work with you and your team to provide installation of the final fabricated product.

We bring…

Expertise

High-Quality

Fast Turnaround

Amazing Design Work

Your FAQs Answered by Our Expert Steel Fabricators

What is steel fabrication?

Using fabrication processes like cutting, forming, joining, and finishing, steel fabrication is the process of converting steel sheet metal into structures, artwork, stair railings, parts and components, and so much more. Steel fabrication can be used for reverse engineering, and OEM replication, as well as creating custom, one-of-a-kind metal works projects.

What materials do you work with for custom steel fabrication?

We domestically source our materials and we work with a variety of variations of steel for both steel sheet fabrication and steel plate fabrication. We utilize products that are galvanized, paintlock, hot rolled, cold rolled, and pickled & oiled.

What types of custom steel fabrication projects do you offer?

There are very few custom steel fabrication projects we can’t tackle. We like to say “If you can imagine it, we can make it a reality!” We love a challenge and are open to seeing your design idea and doing everything we can to bring the design to life. Contact us with details about your project and we’ll be in touch as quickly as possible.

How much does custom steel fabricating cost?

The cost of a steel fabrication project is highly dependent on the extent of the project, materials required, the techniques and equipment that will be used to bring the project to life, and whether or not we will be involved in the installation process. Please reach out to us with the details and design of your project and we’ll provide a no-obligation quote.

How long will it take to complete a custom steel fabrication project?

We pride ourselves on fast turnaround times. That being said, every project is different and there are several factors that will determine how long a project will take. We’ll provide you with an estimated project timeline and completion date during the quoting process.

Other Materials We Work With